Page 154 - DMGT206_PRODUCTION_AND_OPERATIONS_MANAGEMENT

P. 154

Unit 8: Supply Chain Management

and materials management in the 1970s, which evolved into logistics management in the 1980s Notes

and then supply chain management in the 1990s. The reality is that few, if any, organizations

have a department of supply chain management.

Supply chain management encompasses both physical distribution and supply management.

Supply or material management activities focus on the upstream portion of the supply chain

and are mainly concerned with suppliers and inbound logistics. Physical distribution activities

involve that part of the supply chain where work-in-process becomes finished goods and moves

toward customers. Understanding the relationships between the terms is important to being

able to conceptualize a holistic supply chain.

8.1 Materials Management and the Supply Chain

The conceptual basis of the supply chain is not new. Supply chain management is involved with

integrating three key flows across the boundaries of the companies: flow of information, product/

materials, and funds between the different stages. Successful integration or coordination of

these three flows produces improved efficiency and effectiveness for business organizations.

The concept of Supply Chain Management is based on two core ideas:

The first is that practically every product that reaches an end user represents the cumulative

effort of multiple organizations. These organizations are referred to collectively as the

supply chain.

The second idea is that organizations have to pay attention to what is happening outside

their “four walls” and manage the entire chain of activities that ultimately delivers products

to the final customer in order to maximize profits.

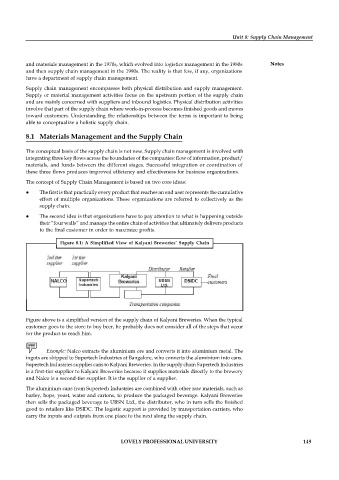

Figure 8.1: A Simplified View of Kalyani Breweries’ Supply Chain

Figure above is a simplified version of the supply chain of Kalyani Breweries. When the typical

customer goes to the store to buy beer, he probably does not consider all of the steps that occur

for the product to reach him.

Example: Nalco extracts the aluminium ore and converts it into aluminium metal. The

ingots are shipped to Supertech Industries at Bangalore, who converts the aluminium into cans.

Supertech Industries supplies cans to Kalyani Breweries. In the supply chain Supertech Industries

is a first-tier supplier to Kalyani Breweries because it supplies materials directly to the brewery

and Nalco is a second-tier supplier. It is the supplier of a supplier.

The aluminium cans from Supertech Industries are combined with other raw materials, such as

barley, hops, yeast, water and cartons, to produce the packaged beverage. Kalyani Breweries

then sells the packaged beverage to UBSN Ltd., the distributor, who in turn sells the finished

good to retailers like DSIDC. The logistic support is provided by transportation carriers, who

carry the inputs and outputs from one place to the next along the supply chain.

LOVELY PROFESSIONAL UNIVERSITY 149