Page 183 - DMGT206_PRODUCTION_AND_OPERATIONS_MANAGEMENT

P. 183

Production and Operations Management

Notes Cost of Ordering: Although it costs money to hold inventory, it also, unfortunately, necessary to

replenish inventory. These costs are called inventory ordering costs. Ordering costs have two

components:

1. One component that is relatively fixed, and

2. Another component that will vary.

It is good to be able to clearly differentiate between those ordering costs that do not change

much and those that are incurred each time an order is placed. The general breakdown between

fixed and variable ordering costs is as follows:

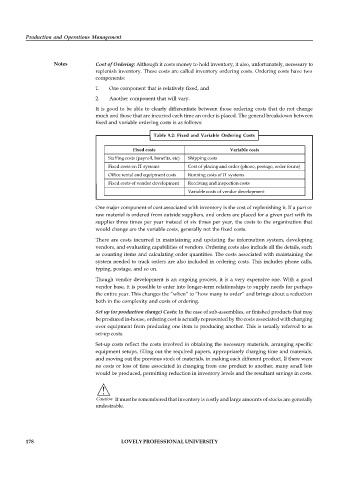

Table 9.2: Fixed and Variable Ordering Costs

Fixed costs Variable costs

Staffing costs (payroll, benefits, etc) Shipping costs

Fixed costs on IT systems Cost of placing and order (phone, postage, order forms)

Office rental and equipment costs Running costs of IT systems

Fixed costs of vendor development Receiving and inspection costs

Variable costs of vendor development

One major component of cost associated with inventory is the cost of replenishing it. If a part or

raw material is ordered from outside suppliers, and orders are placed for a given part with its

supplier three times per year instead of six times per year, the costs to the organization that

would change are the variable costs, generally not the fixed costs.

There are costs incurred in maintaining and updating the information system, developing

vendors, and evaluating capabilities of vendors. Ordering costs also include all the details, such

as counting items and calculating order quantities. The costs associated with maintaining the

system needed to track orders are also included in ordering costs. This includes phone calls,

typing, postage, and so on.

Though vendor development is an ongoing process, it is a very expensive one. With a good

vendor base, it is possible to enter into longer-term relationships to supply needs for perhaps

the entire year. This changes the “when” to “how many to order” and brings about a reduction

both in the complexity and costs of ordering.

Set up (or production change) Costs: In the case of sub-assemblies, or finished products that may

be produced in-house, ordering cost is actually represented by the costs associated with changing

over equipment from producing one item to producing another. This is usually referred to as

set-up costs.

Set-up costs reflect the costs involved in obtaining the necessary materials, arranging specific

equipment setups, filling out the required papers, appropriately charging time and materials,

and moving out the previous stock of materials, in making each different product. If there were

no costs or loss of time associated in changing from one product to another, many small lots

would be produced, permitting reduction in inventory levels and the resultant savings in costs.

!

Caution It must be remembered that inventory is costly and large amounts of stocks are generally

undesirable.

178 LOVELY PROFESSIONAL UNIVERSITY