Page 41 - DCAP608_REAL TIME SYSTEMS

P. 41

Real Time Systems

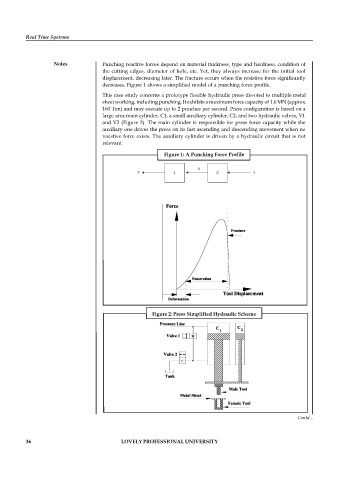

Notes Punching reactive forces depend on material thickness, type and hardness, condition of

the cutting edges, diameter of hole, etc. Yet, they always increase for the initial tool

displacement, decreasing later. The fracture occurs when the resistive force significantly

decreases. Figure 1 shows a simplified model of a punching force profile.

This case study concerns a prototype flexible hydraulic press devoted to multiple metal

sheet working, including punching. It exhibits a maximum force capacity of 1.6 MN (approx.

160 Ton) and may execute up to 2 punches per second. Press configuration is based on a

large area main cylinder, C1, a small auxiliary cylinder, C2, and two hydraulic valves, V1

and V2 (Figure 2). The main cylinder is responsible for press force capacity while the

auxiliary one drives the press on its fast ascending and descending movement when no

resistive force exists. The auxiliary cylinder is driven by a hydraulic circuit that is not

relevant

Figure 1: A Punching Force Profile

u

y f g x

u

y f g x

Figure 2: Press Simplified Hydraulic Scheme

Contd...

36 LOVELY PROFESSIONAL UNIVERSITY