Page 208 - DMGT206_PRODUCTION_AND_OPERATIONS_MANAGEMENT

P. 208

Unit 10: Building of a Supply Chain

Notes

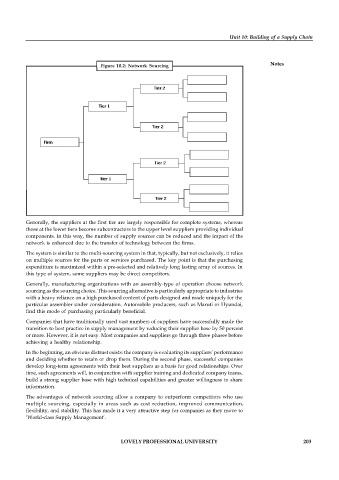

Figure 10.2: Network Sourcing

Generally, the suppliers at the first tier are largely responsible for complete systems, whereas

those at the lower tiers become subcontractors to the upper level suppliers providing individual

components. In this way, the number of supply sources can be reduced and the impact of the

network is enhanced due to the transfer of technology between the firms.

The system is similar to the multi-sourcing system in that, typically, but not exclusively, it relies

on multiple sources for the parts or services purchased. The key point is that the purchasing

expenditure is maximized within a pre-selected and relatively long lasting array of sources. In

this type of system, some suppliers may be direct competitors.

Generally, manufacturing organizations with an assembly-type of operation choose network

sourcing as the sourcing choice. This sourcing alternative is particularly appropriate to industries

with a heavy reliance on a high purchased content of parts designed and made uniquely for the

particular assembler under consideration. Automobile producers, such as Maruti or Hyundai,

find this mode of purchasing particularly beneficial.

Companies that have traditionally used vast numbers of suppliers have successfully made the

transition to best practice in supply management by reducing their supplier base by 50 percent

or more. However, it is not easy. Most companies and suppliers go through three phases before

achieving a healthy relationship.

In the beginning, an obvious distrust exists: the company is evaluating its suppliers’ performance

and deciding whether to retain or drop them. During the second phase, successful companies

develop long-term agreements with their best suppliers as a basis for good relationships. Over

time, such agreements will, in conjunction with supplier training and dedicated company teams,

build a strong supplier base with high technical capabilities and greater willingness to share

information.

The advantages of network sourcing allow a company to outperform competitors who use

multiple sourcing, especially in areas such as cost reduction, improved communication,

flexibility, and stability. This has made it a very attractive step for companies as they move to

‘World-class Supply Management’.

LOVELY PROFESSIONAL UNIVERSITY 203