Page 21 - DMGT206_PRODUCTION_AND_OPERATIONS_MANAGEMENT

P. 21

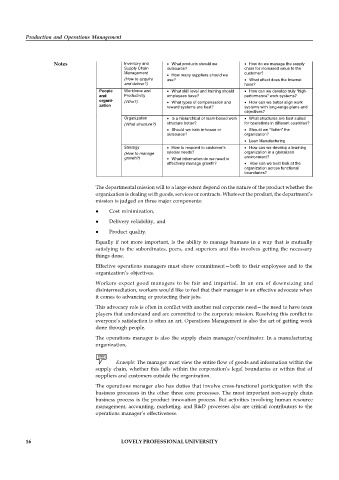

Category

Contemporary Challenges

Decision Area

Products

Structure

Do we produce standard or custom

products and services?

services that are easy to make?

(What?)

How can we coordinate design

Do we make to order or make to

stock?

teams that are scattered across the

world?

Processes

What kind of equipment should we

How do we exploit new IT

use?

developments such as the Internet

(How?)

for rapid and flexible response to

How much of the process should be

customer needs?

automated?

How should processes be

configured?

How much is needed?

Capacity

How do we use flexible capacity

options (such as temporary workers)

(How much?)

What type?

and economies of scope for

When should capacity be increased

competitive advantage?

or decreased?

Facilities

How do we manage and exploit

Where are they located?

global opportunities for locating

(Where?)

What products should be produced

facilities?

in each? Typical Questions How do we design products and

Infra- Quality How do we prevent defects and How can we better learn from

structure Management errors? customers?

(How to improve?) How do we improve products and How can we improve quality to

processes? world-class standards?

Schedule Should scheduling be centralized or How do we use available cost

Production and Operations Management Management decentralized? and financial information in

(When?) How do we prioritize work and/or scheduling?

customer orders? How do we integrate enterprise

resource planning systems into

operations?

Notes Inventory and What products should we How do we manage the supply

Supply Chain outsource? chain for increased value to the

Management customer?

How many suppliers should we

(How to acquire use? What effect does the Internet

and deliver?) have?

People Workforce and What skill level and training should How can we develop truly “high-

and Productivity employees have? performance” work systems?

organi- (Who?) What types of compensation and How can we better align work

zation

reward systems are best? systems with long-range plans and

objectives?

Organization Is a hierarchical or team-based work What structures are best suited

(What structure?) structure better? for operations in different countries?

Should we train in-house or Should we “flatten” the

outsource? organization?

Lean Manufacturing

Strategy How to respond to customer’s How can we develop a learning

(How to manage special needs? organization in a globalized

growth?) What information do we need to environment?

effectively manage growth? How can we best look at the

organization across functional

boundaries?

The departmental mission will to a large extent depend on the nature of the product whether the

organization is dealing with goods, services or contracts. Whatever the product, the department’s

mission is judged on three major components:

Cost minimization,

Delivery reliability, and

Product quality.

Equally if not more important, is the ability to manage humans in a way that is mutually

satisfying to the subordinates, peers, and superiors and this involves getting the necessary

things done.

Effective operations managers must show commitment—both to their employees and to the

organization’s objectives.

Workers expect good managers to be fair and impartial. In an era of downsizing and

disintermediation, workers would like to feel that their manager is an effective advocate when

it comes to advancing or protecting their jobs.

This advocacy role is often in conflict with another real corporate need—the need to have team

players that understand and are committed to the corporate mission. Resolving this conflict to

everyone’s satisfaction is often an art. Operations Management is also the art of getting work

done through people.

The operations manager is also the supply chain manager/coordinator. In a manufacturing

organization,

Example: The manager must view the entire flow of goods and information within the

supply chain, whether this falls within the corporation’s legal boundaries or within that of

suppliers and customers outside the organization.

The operations manager also has duties that involve cross-functional participation with the

business processes in the other three core processes. The most important non-supply chain

business process is the product innovation process. But activities involving human resource

management, accounting, marketing, and R&D processes also are critical contributors to the

operations manager’s effectiveness.

16 LOVELY PROFESSIONAL UNIVERSITY