Page 296 - DMGT206_PRODUCTION_AND_OPERATIONS_MANAGEMENT

P. 296

Unit 14: Operations Scheduling

Notes

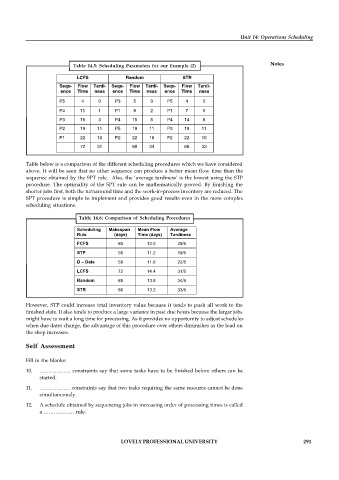

Table 14.5: Scheduling Parameters for our Example (2)

LCFS Random STR

Sequ- Flow Tardi- Sequ- Flow Tardi- Sequ- Flow Tardi-

ence Time ness ence Time ness ence Time ness

P5 4 0 P3 5 0 P5 4 0

P4 11 1 P1 8 2 P1 7 0

P3 16 3 P4 15 5 P4 14 6

P2 19 11 P5 19 11 P3 19 11

P1 22 16 P2 22 16 P2 22 16

72 31 69 34 66 33

Table below is a comparison of the different scheduling procedures which we have considered

above. It will be seen that no other sequence can produce a better mean flow time than the

sequence obtained by the SPT rule. Also, the ‘average tardiness’ is the lowest using the STP

procedure. The optimality of the SPT rule can be mathematically proved. By finishing the

shorter jobs first, both the turnaround time and the work-in-process inventory are reduced. The

SPT procedure is simple to implement and provides good results even in the more complex

scheduling situations.

Table 14.6: Comparison of Scheduling Procedures

Scheduling Makespan Mean Flow Average

Rule (days) Time (days) Tardiness

FCFS 60 12.0 29/5

STP 56 11.2 19/5

D – Date 58 11.6 22/5

LCFS 72 14.4 31/5

Random 69 13.8 34/5

STR 66 13.2 33/5

However, STP could increase total inventory value because it tends to push all work to the

finished state. It also tends to produce a large variance in past due hours because the larger jobs

might have to wait a long time for processing. As it provides no opportunity to adjust schedules

when due dates change, the advantage of this procedure over others diminishes as the load on

the shop increases.

Self Assessment

Fill in the blanks:

10. ……………… constraints say that some tasks have to be finished before others can be

started.

11. ……………… constraints say that two tasks requiring the same resource cannot be done

simultaneously.

12. A schedule obtained by sequencing jobs in increasing order of processing times is called

a ……………… rule.

LOVELY PROFESSIONAL UNIVERSITY 291