Page 139 - DCAP601_SIMULATION_AND_MODELING

P. 139

Unit 8: Simulation of Queuing System (II)

The flexible budget (100 per cent capacity 20,000 kg) is shown in Table 5. Notes

Sub-contracting:

Cost (4,000 x 105) = ` 4,20,000

Variable cost (mfg) 4,000 x 102 = ` 4,08,000

Incremental cost on sub-contracting — ` 12,000

Increase in fixed cost saved — ` 1,12,700

Increase in fixed cost saved — ` 1,12,700

Net saving — ` 1,00,700

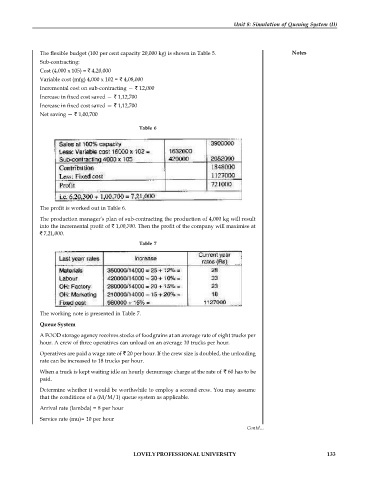

Table 6

The profit is worked out in Table 6.

The production manager’s plan of sub-contracting the production of 4,000 kg will result

into the incremental profit of ` 1,00,700. Then the profit of the company will maximise at

` 7,21,000.

Table 7

The working note is presented in Table 7.

Queue System

A FOOD storage agency receives stocks of foodgrains at an average rate of eight trucks per

hour. A crew of three operatives can unload on an average 10 trucks per hour.

Operatives are paid a wage rate of ` 20 per hour. If the crew size is doubled, the unloading

rate can be increased to 18 trucks per hour.

When a truck is kept waiting idle an hourly demurrage charge at the rate of ` 60 has to be

paid.

Determine whether it would be worthwhile to employ a second crew. You may assume

that the conditions of a (M/M/1) queue system as applicable.

Arrival rate (lambda) = 8 per hour

Service rate (mu)= 10 per hour

Contd...

LOVELY PROFESSIONAL UNIVERSITY 133