Page 176 - DMGT206_PRODUCTION_AND_OPERATIONS_MANAGEMENT

P. 176

Unit 8: Supply Chain Management

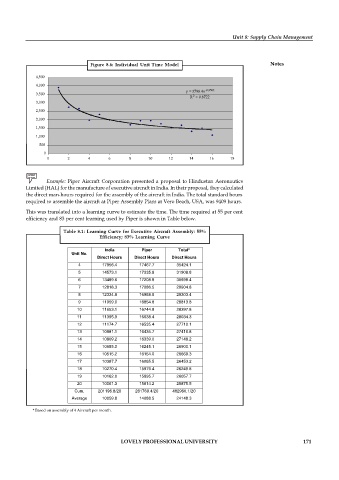

Figure 8.6: Individual Unit Time Model Notes

4,500

4,000

y = 3798.4x -0.3582

3,500

2

R = 0.8722

3,000

2,500

2,000

1,500

1,000

500

0

0 2 4 6 8 10 12 14 16 18

Example: Piper Aircraft Corporation presented a proposal to Hindustan Aeronautics

Limited (HAL) for the manufacture of executive aircraft in India. In their proposal, they calculated

the direct man-hours required for the assembly of the aircraft in India. The total standard hours

required to assemble the aircraft at Piper Assembly Plant at Vero Beach, USA, was 9409 hours.

This was translated into a learning curve to estimate the time. The time required at 55 per cent

efficiency and 83 per cent learning used by Piper is shown in Table below.

Table 8.1: Learning Curve for Executive Aircraft Assembly: 55%

Efficiency; 83% Learning Curve

India Piper Total*

Unit No.

Direct Hours Direct Hours Direct Hours

4 17956.4 17467.7 35424.1

5 14573.1 17335.8 31908.8

6 13489.6 17208.8 30698.4

7 12818.3 17086.5 29904.8

8 12334.8 16968.6 29303.4

9 11959.0 16854.8 28813.8

10 11653.1 16744.8 28397.8

11 11395.9 16638.4 28034.3

12 11174.7 16535.4 27710.1

13 10981.1 16435.7 27416.8

14 10809.2 16339.0 27148.2

15 10655.0 16245.1 26900.1

16 10515.2 16154.0 26669.3

17 10387.7 16065.5 26453.2

18 10270.4 15979.4 26249.8

19 10162.0 15895.7 26057.7

20 10061.3 15814.2 25875.5

Cum. 201196.8/20 281769.4/20 482966.1/20

Average 10059.8 14088.5 24148.3

* Based on assembly of 4 Aircraft per month.

LOVELY PROFESSIONAL UNIVERSITY 171