Page 228 - DMGT206_PRODUCTION_AND_OPERATIONS_MANAGEMENT

P. 228

Unit 11: Facility Planning and Layout

This layout is suitable when a large variety of products are needed in small volumes (or batches). Notes

The group technology principle suggests that parts which are similar in design or manufacturing

operations are grouped into one family, called a part-family. For each part-family, a dedicated

cluster of machines (called ‘machine cells’) are identified. Generally, all the processing

requirements of a particular part-family are completed in its corresponding machine cell,

eliminating inter-cell transfers of the part.

Group technology and Cellular Layouts can be combined and used to produce families of parts

more economically than can traditional process or product layouts. Data is gathered to identify

parts with similar characteristics, which are also manufactured similarly. Groups of items can be

formed either according to similarities in their design (external features such as size, shape, use,

etc.) or according to similarities in their manufacturing process. This is a time-consuming and

tedious task, which can be accomplished by the following methods:

1. Visual inspection method (for grouping items according to design similarities), which is

very simple in application but not very accurate.

2. Examination of design and production data (for grouping items according to design

similarities), which is more complex to implement than visual inspection but much more

accurate.

3. Analysis of the production flow of items (for grouping items according to manufacturing

process similarities).

This identification and coding is the chart of group technology. The equipment to make these is

grouped together and designated for these parts. To some extent, a process layout, characteristic

of job shops, is changed to a small well-defined product layout. This group of equipment is

called a cell, and the arrangement of cells is called a Cellular Layout.

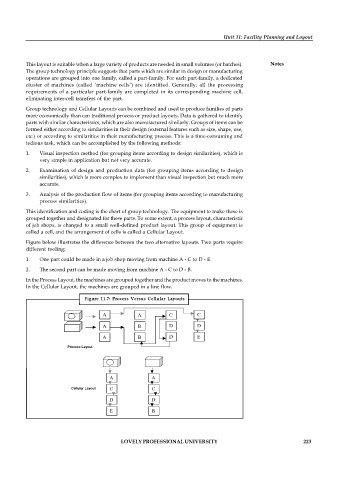

Figure below illustrates the difference between the two alternative layouts. Two parts require

different tooling;

1. One part could be made in a job shop moving from machine A - C to D - E.

2. The second part can be made moving from machine A - C to D - B.

In the Process Layout, the machines are grouped together and the product moves to the machines.

In the Cellular Layout, the machines are grouped in a line flow.

Figure 11.7: Process Versus Cellular Layouts

A A C C

A B D D

A B D E

Process Layout

A A

Cellular Layout C C

D D

E B

LOVELY PROFESSIONAL UNIVERSITY 223