Page 277 - DMGT206_PRODUCTION_AND_OPERATIONS_MANAGEMENT

P. 277

Production and Operations Management

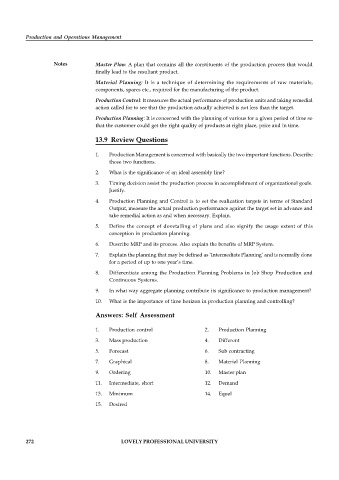

Notes Master Plan: A plan that contains all the constituents of the production process that would

finally lead to the resultant product.

Material Planning: It is a technique of determining the requirements of raw materials,

components, spares etc., required for the manufacturing of the product.

Production Control: It measures the actual performance of production units and taking remedial

action called for to see that the production actually achieved is not less than the target.

Production Planning: It is concerned with the planning of various for a given period of time so

that the customer could get the right quality of products at right place, price and in time.

13.9 Review Questions

1. Production Management is concerned with basically the two important functions. Describe

those two functions.

2. What is the significance of an ideal assembly line?

3. Timing decision assist the production process in accomplishment of organizational goals.

Justify.

4. Production Planning and Control is to set the realization targets in terms of Standard

Output, measure the actual production performance against the target set in advance and

take remedial action as and when necessary. Explain.

5. Define the concept of dovetailing of plans and also signify the usage extent of this

conception in production planning.

6. Describe MRP and its process. Also explain the benefits of MRP System.

7. Explain the planning that may be defined as ‘Intermediate Planning’ and is normally done

for a period of up to one year’s time.

8. Differentiate among the Production Planning Problems in Job Shop Production and

Continuous Systems.

9. In what way aggregate planning contribute its significance to production management?

10. What is the importance of time horizon in production planning and controlling?

Answers: Self Assessment

1. Production control 2. Production Planning

3. Mass production 4. Different

5. Forecast 6. Sub contracting

7. Graphical 8. Material Planning

9. Ordering 10. Master plan

11. Intermediate, short 12. Demand

13. Minimum 14. Equal

15. Desired

272 LOVELY PROFESSIONAL UNIVERSITY