Page 103 - DMGT501_OPERATIONS_MANAGEMENT

P. 103

Unit 4: Process Selection and Facility Layout

4. Volume Flexibility: The ability of the transformation process to profitably accommodate Notes

variations in production quantities. Systems with high fixed costs beget inflexibility since

the firm will always be striving to maintain high utilization rates.

5. Rerouting Program Flexibility: The ability of the Operations Management systems to

respond to factors of product shortfall, such as equipment breakdowns, labour absenteeism,

or a delayed raw materials shipment.

6. Material Flexibility: The ability of transformation processes to adjust for unexpected

input variations.

7. Flexibility Responsiveness: The ability of the firm and its managers to change the strategic

objectives in response to changes in the market place.

Enhancing flexibility requires co-operation both inside and outside the firm. For example, a

suitably designed product greatly enhances the ability of the operations manager, to implement

and compete, using product modification flexibility. To emphasize volume flexibility, a firm

needs the support of suppliers. Success in enhancing mix or changeover flexibility depends on

strong links with the internal marketing function and with customers and its supply chain

management system.

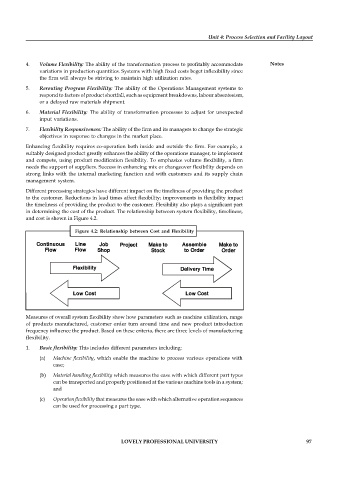

Different processing strategies have different impact on the timeliness of providing the product

to the customer. Reductions in lead times affect flexibility; improvements in flexibility impact

the timeliness of providing the product to the customer. Flexibility also plays a significant part

in determining the cost of the product. The relationship between system flexibility, timeliness,

and cost is shown in Figure 4.2.

Figure 4.2: Relationship between Cost and Flexibility

Continuous Line Job Project Make to Assemble Make to

Flow Flow Shop Stock to Order Order

Flexibility Delivery Time

Low Cost Low Cost

Measures of overall system flexibility show how parameters such as machine utilization, range

of products manufactured, customer order turn around time and new product introduction

frequency influence the product. Based on these criteria, there are three levels of manufacturing

flexibility.

1. Basic flexibility: This includes different parameters including:

(a) Machine flexibility, which enable the machine to process various operations with

ease;

(b) Material handling flexibility which measures the ease with which different part types

can be transported and properly positioned at the various machine tools in a system;

and

(c) Operation flexibility that measures the ease with which alternative operation sequences

can be used for processing a part type.

LOVELY PROFESSIONAL UNIVERSITY 97