Page 4 - DMGT501_OPERATIONS_MANAGEMENT

P. 4

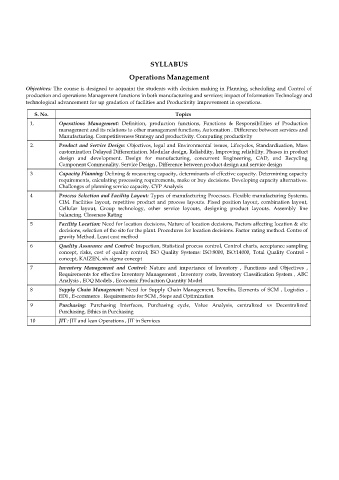

SYLLABUS

Operations Management

Objectives: The course is designed to acquaint the students with decision making in Planning, scheduling and Control of

production and operations Management functions in both manufacturing and services; impact of Information Technology and

technological advancement for up gradation of facilities and Productivity Improvement in operations.

S. No. Topics

1. Operations Management: Definition, production functions, Functions & Responsibilities of Production

management and its relations to other management functions, Automation . Difference between services and

Manufacturing. Competitiveness Strategy and productivity. Computing productivity

2. Product and Service Design: Objectives, legal and Environmental issues, Lifecycles, Standardization, Mass

customization Delayed Differentiation. Modular design, Reliability, Improving reliability. Phases in product

design and development. Design for manufacturing, concurrent Engineering, CAD, and Recycling

Component Commonality. Service Design , Difference between product design and service design

3 Capacity Planning: Defining & measuring capacity, determinants of effective capacity. Determining capacity

requirements, calculating processing requirements, make or buy decisions. Developing capacity alternatives.

Challenges of planning service capacity. CVP Analysis

4 Process Selection and Facility Layout: Types of manufacturing Processes. Flexible manufacturing Systems,

CIM. Facilities layout, repetitive product and process layouts. Fixed position layout, combination layout,

Cellular layout, Group technology, other service layouts, designing product layouts. Assembly line

balancing. Closeness Rating

5 Facility Location: Need for location decisions, Nature of location decisions, Factors affecting location & site

decisions, selection of the site for the plant. Procedures for location decisions. Factor rating method. Centre of

gravity Method. Least cost method

6 Quality Assurance and Control: Inspection, Statistical process control, Control charts, acceptance sampling

concept, risks, cost of quality control; ISO Quality Systems: ISO:9000, ISO:14000, Total Quality Control -

concept, KAIZEN, six sigma concept

7 Inventory Management and Control: Nature and importance of Inventory , Functions and Objectives ,

Requirements for effective Inventory Management , Inventory costs, Inventory Classification System , ABC

Analysis , EOQ Models , Economic Production Quantity Model

8 Supply Chain Management: Need for Supply Chain Management, Benefits, Elements of SCM , Logistics ,

EDI , E-commerce . Requirements for SCM , Steps and Optimization

9 Purchasing: Purchasing Interfaces, Purchasing cycle, Value Analysis, centralized vs Decentralized

Purchasing. Ethics in Purchasing

10 JIT : JIT and lean Operations , JIT in Services