Page 71 - DCOM202_COST_ACCOUNTING_I

P. 71

Unit 4: Material Control

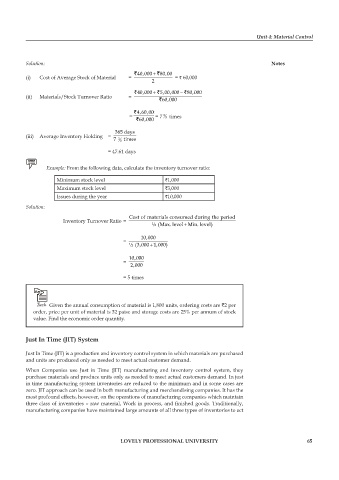

Solution: Notes

,

,

`40 000 + `80 00

(i) Cost of Average Stock of Material = = ` 60,000

2

`40 000 + , `500 000 − , , `80 000

,

(ii) Materials/Stock Turnover Ratio = `60 000

,

`460 000

,

,

= = 7 2 3 times

,

`60 000

365 days

(iii) Average Inventory Holding =

7 times

2

3

= 47.61 days

Example: From the following data, calculate the inventory turnover ratio:

Minimum stock level `1,000

Maximum stock level `3,000

Issues during the year `10,000

Solution:

Cost of materialsconsumedduringthe period

Inventory Turnover Ratio =

½( Maxlevel + MMinlevel. )

.

,

10 000

=

,

+

½( 3 000 1 000)

,

,

10 000

=

2 000

,

= 5 times

Task Given the annual consumption of material is 1,800 units, ordering costs are `2 per

order, price per unit of material is 32 paise and storage costs are 25% per annum of stock

value. Find the economic order quantity.

Just In Time (JIT) System

Just In Time (JIT) is a production and inventory control system in which materials are purchased

and units are produced only as needed to meet actual customer demand.

When Companies use Just in Time (JIT) manufacturing and inventory control system, they

purchase materials and produce units only as needed to meet actual customers demand. In just

in time manufacturing system inventories are reduced to the minimum and in some cases are

zero. JIT approach can be used in both manufacturing and merchandising companies. It has the

most profound effects, however, on the operations of manufacturing companies which maintain

three class of inventories – raw material, Work in process, and finished goods. Traditionally,

manufacturing companies have maintained large amounts of all three types of inventories to act

LOVELY PROFESSIONAL UNIVERSITY 65