Page 217 - DMGT206_PRODUCTION_AND_OPERATIONS_MANAGEMENT

P. 217

Production and Operations Management

Notes customers to wait for their turns; it could be a machine, a workbench or workstation; it could be

a stairway or an aisle; it could be a cafeteria or storage space. These have many practical and

strategic implications.

The goal of functional layout is to allow workers and equipment to operate as effectively as

possible. In order to do so, the following questions need to be addressed:

1. What should the layout include for each economic activity center? The economic activity

center should reflect decisions that maximize productivity.

Example: A central tool room is often efficient for most processes, but keeping tools at

individual workstations makes more sense for many processes.

2. How much space and capacity does each economic activity center need? Space is a cost but

inadequate space can reduce productivity and even create safety and health hazards.

3. How should each economic activity center’s space be configured? The space, its shape, and

the elements need to be interrelated.

Example: In a store the placement of the show windows, spaces planned so that products

are visible and providing a pleasing atmosphere are necessary parts of the layout configuration

decisions.

Did u know? What is Economic Activity center?

Economic activity centers are work related places that consume space.

The location of an economic activity center has two dimensions that affect a center’s performance:

1. Relative location, or the placement of a center relative to other centers, and

2. Absolute location or the particular space that the center occupies within the facility, both.

Where should each economic activity center be located? Location can significantly affect

productivity. Employees who must frequently interact with one another should be placed close

together so that interaction becomes easier; sections or departments should be planned to reduce

time lost in moving material or traveling of personnel back and forth.

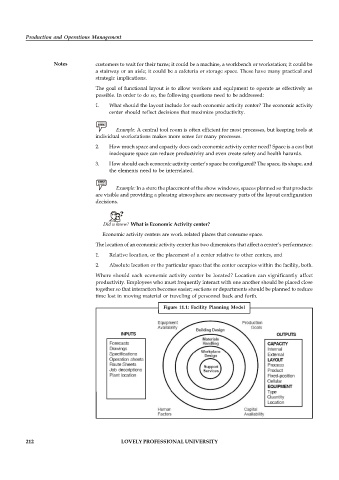

Figure 11.1: Facility Planning Model

212 LOVELY PROFESSIONAL UNIVERSITY