Page 218 - DMGT206_PRODUCTION_AND_OPERATIONS_MANAGEMENT

P. 218

Unit 11: Facility Planning and Layout

The operations function in both manufacturing and service organizations can be divided into Notes

two basic types, intermittent and continuous, according to the volume and standardizing of the

product or service.

Different types of operations have different layout requirements. By their nature, layouts of the

facility are one of the most important strategic elements of a business enterprise. Many symptoms

of inappropriate business architecture appear as layout or material handling issues.

Example: In warehouses, materials flows and the cost of picking stocks are dominant

considerations; in retail outlets, customer convenience and sales may dominate; whereas in an

office, communication effectiveness and team building may be crucial.

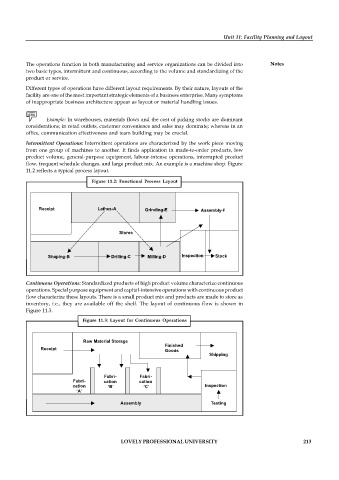

Intermittent Operations: Intermittent operations are characterized by the work piece moving

from one group of machines to another. It finds application in made-to-order products, low

product volume, general-purpose equipment, labour-intense operations, interrupted product

flow, frequent schedule changes, and large product mix. An example is a machine shop. Figure

11.2 reflects a typical process layout.

Figure 11.2: Functional Process Layout

Receipt Lathes-A Grinding-E Assembly-F

Stores

Shaping-B Drilling-C Milling-D Inspection Stock

Continuous Operations: Standardized products of high product volume characterize continuous

operations. Special purpose equipment and capital-intensive operations with continuous product

flow characterize these layouts. There is a small product mix and products are made to store as

inventory, i.e., they are available off the shelf. The layout of continuous flow is shown in

Figure 11.3.

Figure 11.3: Layout for Continuous Operations

Raw Material Storage

Receipt Finished

Goods

Shipping

Fabri- Fabri-

Fabri- cation cation

cation ‘B’ ‘C’ Inspection

‘A’

Assembly Testing

LOVELY PROFESSIONAL UNIVERSITY 213