Page 262 - DMGT206_PRODUCTION_AND_OPERATIONS_MANAGEMENT

P. 262

Unit 13: Production Planning and Control

be planned accurately with the help of mathematical calculations. This planning of work-in- Notes

progress of the finished goods is known as Material Requirement Planning (or MRP).

Notes While doing Material Requirement Planning one has to look for the following

things:

1. All the components, sub-assemblies and assemblies are known so that they all can

participate for the planning of required materials.

2. The lead time of all the assemblies and sub-assemblies should be known.

3. The inventory already in hand should be considered for the present Material

Requirement Planning.

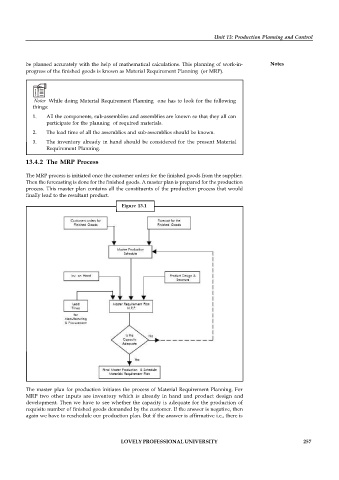

13.4.2 The MRP Process

The MRP process is initiated once the customer orders for the finished goods from the supplier.

Then the forecasting is done for the finished goods. A master plan is prepared for the production

process. This master plan contains all the constituents of the production process that would

finally lead to the resultant product.

Figure 13.1

The master plan for production initiates the process of Material Requirement Planning. For

MRP two other inputs are inventory which is already in hand and product design and

development. Then we have to see whether the capacity is adequate for the production of

requisite number of finished goods demanded by the customer. If the answer is negative, then

again we have to reschedule our production plan. But if the answer is affirmative i.e., there is

LOVELY PROFESSIONAL UNIVERSITY 257