Page 284 - DMGT206_PRODUCTION_AND_OPERATIONS_MANAGEMENT

P. 284

Unit 14: Operations Scheduling

‘thrash’. ‘Thrashing’ is the problem of the system keeping itself busy re-planning rather than Notes

producing, which effectively reduces capacity. This results in problems similar to mainframe

computers where this problem was first documented, lots of expediting, customer panics and

increased changeovers. The result is an effective reduction in batch sizes, as you spend more

time changing over than producing due to batch splitting.

Figure 14.1 shows a gradual increase in lead time as load increases up to the point where

‘thrashing’ occurs and where lead times go through the roof.

14.1.7 Input-output Control

Output plans and schedules call for certain levels of capacity at a work center and those jobs are

completed at a specific time on every facility. In a real world situation, the utilization of the

capacity of a facility may be different from the plans – under-utilization of capacity means

wasted resources and over-utilization may cause disruption, failure, and delays. These differences

are monitored through input-output reports.

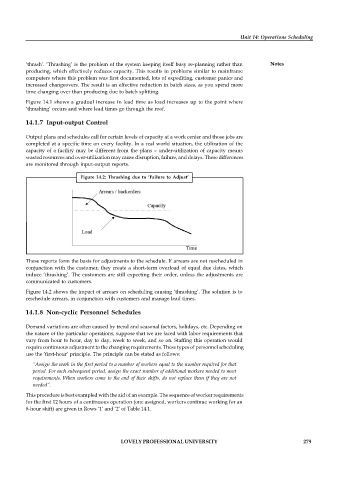

Figure 14.2: Thrashing due to ‘Failure to Adjust’

These reports form the basis for adjustments to the schedule. If arrears are not rescheduled in

conjunction with the customer, they create a short-term overload of equal due dates, which

induce ‘thrashing’. The customers are still expecting their order, unless the adjustments are

communicated to customers.

Figure 14.2 shows the impact of arrears on scheduling causing ‘thrashing’. The solution is to

reschedule arrears, in conjunction with customers and manage lead times.

14.1.8 Non-cyclic Personnel Schedules

Demand variations are often caused by trend and seasonal factors, holidays, etc. Depending on

the nature of the particular operations, suppose that we are faced with labor requirements that

vary from hour to hour, day to day, week to week, and so on. Staffing this operation would

require continuous adjustment to the changing requirements. These types of personnel scheduling

use the ‘first-hour’ principle. The principle can be stated as follows:

“Assign the work in the first period to a number of workers equal to the number required for that

period. For each subsequent period, assign the exact number of additional workers needed to meet

requirements. When workers come to the end of their shifts, do not replace them if they are not

needed”.

This procedure is best exampled with the aid of an example. The sequence of worker requirements

for the first 12 hours of a continuous operation (one assigned, workers continue working for an

8-hour shift) are given in Rows ‘1’ and ‘2’ of Table 14.1.

LOVELY PROFESSIONAL UNIVERSITY 279