Page 108 - DCAP302_ENTERPRISE_RESOURCE_PLANNING

P. 108

Enterprise Resource Planning

notes Invoice Verification in Materials Management serves the following purposes:

1. It completes the materials procurement process - which starts with the purchase requisition,

continues with purchasing and goods receipt and ends with the invoice receipt. It allows

invoices that do not originate in materials procurement (for example, services, expenses,

course costs, etc.) to be processed.

2. It allows credit memos to be processed, either as invoice cancellations or discounts. Invoice

Verification does not handle the payment or the analysis of invoices. The information

required for these processes are passed on to other departments.

Invoice Verification Tasks include:

Entering invoices and credit memos that have been received. Checking the accuracy of invoices

with respect to contents, prices, and arithmetic. Executing the account postings resulting from an

invoice. Updating certain data in the ERP system, for example, open items and material prices.

Checking invoices that were blocked because they varied too greatly from the purchase order.

The high degree of integration in the ERP system allows these tasks to be carried out smoothly

and efficiently.

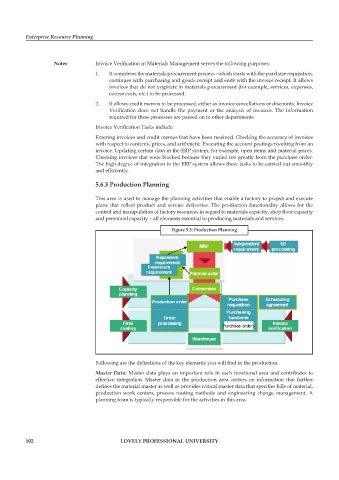

5.6.3 production planning

This area is used to manage the planning activities that enable a factory to project and execute

plans that reflect product and service deliveries. The production functionality allows for the

control and manipulation of factory resources in regard to materials capacity, shop floor capacity

and personnel capacity – all elements essential to producing materials and services.

figure 5.3: production planning

Following are the definitions of the key elements you will find in the production.

Master Data: Master data plays an important role in each functional area and contributes to

effective integration. Master data in the production area centers on information that further

defines the material master as well as provides critical master data that specifies bills of material,

production work centers, process routing methods and engineering change management. A

planning team is typically responsible for the activities in this area.

102 LoveLy professionaL university