Page 227 - DCAP302_ENTERPRISE_RESOURCE_PLANNING

P. 227

Unit 14: Case Study – ERP Application on Supply Chain

notes

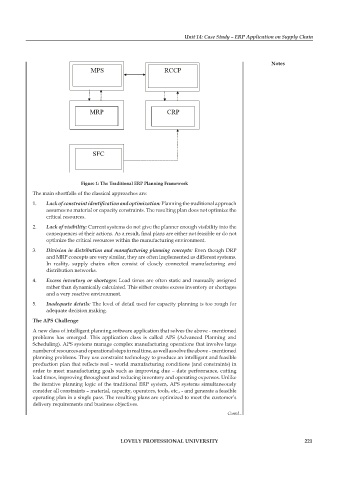

MPS RCCP

MRP CRP

SFC

figure 1: the traditional erp planning framework

The main shortfalls of the classical approaches are:

1. Lack of constraint identification and optimization: Planning the traditional approach

assumes no material or capacity constraints. The resulting plan does not optimize the

critical resources.

2. Lack of visibility: Current systems do not give the planner enough visibility into the

consequences of their actions. As a result, final plans are either not feasible or do not

optimize the critical resources within the manufacturing environment.

3. Division in distribution and manufacturing planning concepts: Even though DRP

and MRP concepts are very similar, they are often implemented as different systems.

In reality, supply chains often consist of closely connected manufacturing and

distribution networks.

4. Excess inventory or shortages: Lead times are often static and manually assigned

rather than dynamically calculated. This either creates excess inventory or shortages

and a very reactive environment.

5. Inadequate details: The level of detail used for capacity planning is too rough for

adequate decision making.

the aps challenge

A new class of intelligent planning software application that solves the above - mentioned

problems has emerged. This application class is called APS (Advanced Planning and

Scheduling). APS systems manage complex manufacturing operations that involve large

number of resources and operational steps in real time, as well as solve the above – mentioned

planning problems. They use constraint technology to produce an intelligent and feasible

production plan that reflects real – world manufacturing conditions (and constraints) in

order to meet manufacturing goals such as improving due – date performance, cutting

lead times, improving throughout and reducing inventory and operating expenses. Unlike

the iterative planning logic of the traditional ERP system, APS systems simultaneously

consider all constraints – material, capacity, operators, tools, etc., - and generate a feasible

operating plan in a single pass. The resulting plans are optimized to meet the customer’s

delivery requirements and business objectives.

Contd...

LoveLy professionaL university 221