Page 120 - DMGT501_OPERATIONS_MANAGEMENT

P. 120

Operations Management

Notes

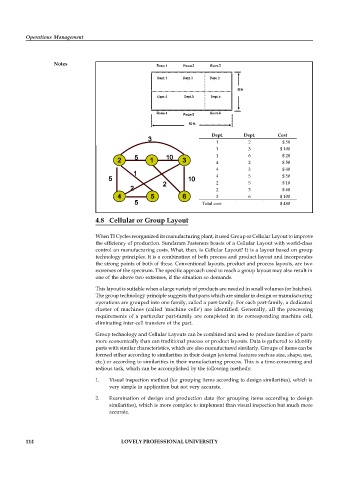

Dept. Dept. Cost

3

1 2 $ 50

0 1 3 $ 100

5 10 1 6 $ 20

2 1 3

0 0 4 2 $ 50

4 3 $ 40

1 4 5 $ 50

5 0 10

0 2 2 0 2 5 $ 10

$ 60

2

3

0

4 0 5 6 3 6 $ 100

5 Total cost $ 480

0

4.8 Cellular or Group Layout

When TI Cycles reorganized its manufacturing plant, it used Group or Cellular Layout to improve

the efficiency of production. Sundaram Fasteners boasts of a Cellular Layout with world-class

control on manufacturing costs. What, then, is Cellular Layout? It is a layout based on group

technology principles. It is a combination of both process and product layout and incorporates

the strong points of both of these. Conventional layouts, product and process layouts, are two

extremes of the spectrum. The specific approach used to reach a group layout may also result in

one of the above two extremes, if the situation so demands.

This layout is suitable when a large variety of products are needed in small volumes (or batches).

The group technology principle suggests that parts which are similar in design or manufacturing

operations are grouped into one family, called a part-family. For each part-family, a dedicated

cluster of machines (called 'machine cells') are identified. Generally, all the processing

requirements of a particular part-family are completed in its corresponding machine cell,

eliminating inter-cell transfers of the part.

Group technology and Cellular Layouts can be combined and used to produce families of parts

more economically than can traditional process or product layouts. Data is gathered to identify

parts with similar characteristics, which are also manufactured similarly. Groups of items can be

formed either according to similarities in their design (external features such as size, shape, use,

etc.) or according to similarities in their manufacturing process. This is a time-consuming and

tedious task, which can be accomplished by the following methods:

1. Visual inspection method (for grouping items according to design similarities), which is

very simple in application but not very accurate.

2. Examination of design and production data (for grouping items according to design

similarities), which is more complex to implement than visual inspection but much more

accurate.

114 LOVELY PROFESSIONAL UNIVERSITY