Page 154 - DMGT523_LOGISTICS_AND_SUPPLY_CHAIN_MANAGEMENT

P. 154

Unit 7: Inventory Management

Notes

Example: High inventory at retail outlets may help in making the goods easily available

to customers and also result in a growth in sales, but it will also increase costs and bring down

profitability.

These are two major issues in conflict with each other that need to be resolved, in order to

optimize the inventory carried by the organization.

Excess inventory is a cost burden to industry in terms of capital tied up, the cost of obsolescence

and the cost of servicing product in the supply chain. However, having the right amount of

inventory to meet customer requirements is critical. Inventory management is about two things:

not running out, and not having too much.

Essentially, inventory is a reserve system to prevent stockouts. However, as important as it is to

prevent such a stockout, you also don’t want to hold onto too much inventory because holding

costs can become a major encumbrance. So how do you balance the two and what is the right

amount? More importantly, when should you reorder in order to prevent a stockout. The answer

to this can be determined by obtaining and applying the appropriate inventory models in

decision-making.

The heart of inventory decisions lies in the identification of inventory costs and optimizing the

costs relative to the operations of the organization. As inventory is a necessary but idle resource,

stock levels and inventory costs in manufacturing need to be minimized.

Notes Large holdings of inventory also cause long cycle times which may not be desirable.

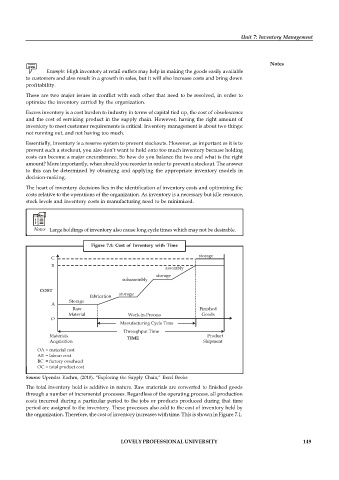

Figure 7.1: Cost of Inventory with Time

C storage

B

assembly

storage

subassembly

COST

fabrication storage

Storage

A

Raw Finished

Material Work-in-Process Goods

O

Manufacturing Cycle Time

Throughput Time

Materials TIME Product

Acquisition Shipment

OA = material cost

AB = labour cost

BC = factory overhead

OC = total product cost

Source: Upendra Kachru, (2010), “Exploring the Supply Chain,” Excel Books

The total inventory held is additive in nature. Raw materials are converted to finished goods

through a number of incremental processes. Regardless of the operating process, all production

costs incurred during a particular period to the jobs or products produced during that time

period are assigned to the inventory. These processes also add to the cost of inventory held by

the organization. Therefore, the cost of inventory increases with time. This is shown in Figure 7.1.

LOVELY PROFESSIONAL UNIVERSITY 149