Page 78 - DMGT206_PRODUCTION_AND_OPERATIONS_MANAGEMENT

P. 78

Unit 4: Quality Control

(iii) The value of A . From tables the values are given. Notes

2

For n = 5, A = 0.577, D = 0 and D = 2115.

2 3 4

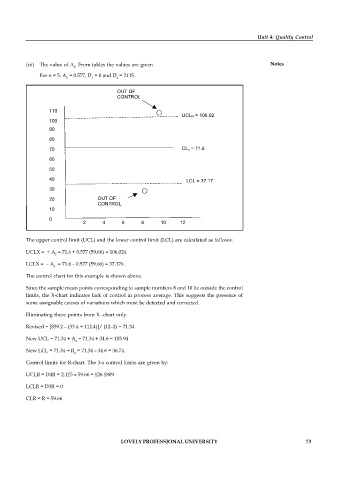

OUT OF

CONTROL

110

UCLR = 106.02

100

90

80

70 CLx = 71.6

60

50

40 LCL = 37.17

30

20 OUT OF

CONTROL

10

0

2 4 6 8 10 12

The upper control limit (UCL) and the lower control limit (LCL) are calculated as follows:

UCLX = + A = 71.6 + 0.577 (59.66) = 106.024

2

LCLX = – A = 71.6 – 0.577 (59.66) = 37.176.

2

The control chart for this example is shown above.

Since the sample mean points corresponding to sample numbers 8 and 10 lie outside the control

limits, the X-chart indicates lack of control in process average. This suggests the presence of

some assignable causes of variations which must be detected and corrected.

Eliminating these points from X -chart only.

Revised = [859.2 – (33.4 + 112.4)]/ (12–2) = 71.34

New UCL = 71.34 + A = 71.34 + 34.6 = 105.94

2

New LCL = 71.34 + R = 71.34 – 34.6 = 36.74.

2

Control limits for R-chart. The 3-s control limits are given by:

UCLR = D4R = 2.115 59.66 = 126.1809

LCLR = D3R = 0

CLR = R = 59.66

LOVELY PROFESSIONAL UNIVERSITY 73