Page 263 - DMGT501_OPERATIONS_MANAGEMENT

P. 263

Unit 11: Inventory Model

Notes

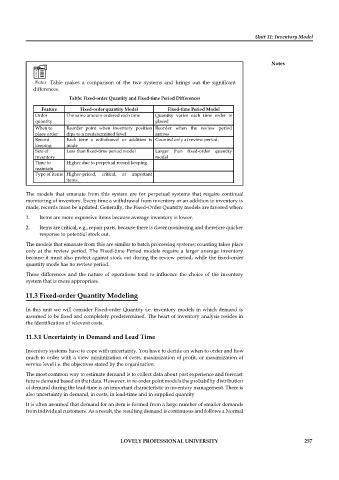

Table makes a comparison of the two systems and brings out the significant

differences.

Table: Fixed-order Quantity and Fixed-time Period Differences

Feature Fixed-order quantity Model Fixed-time Period Model

Order The same amount ordered each time Quantity varies each time order is

quantity placed

When to Reorder point when inventory position Reorder when the review period

place order dips to a predetermined level arrives

Record Each time a withdrawal or addition is Counted only at review period.

keeping made

Size of Less than fixed-time period model Larger than fixed-order quantity

inventory model

Time to Higher due to perpetual record keeping

maintain

Type of items Higher-priced, critical, or important

items.

The models that emanate from this system are for perpetual systems that require continual

monitoring of inventory. Every time a withdrawal from inventory or an addition to inventory is

made, records must be updated. Generally, the Fixed-Order Quantity models are favored when:

1. Items are more expensive items because average inventory is lower.

2. Items are critical, e.g., repair parts, because there is closer monitoring and therefore quicker

response to potential stock out.

The models that emanate from this are similar to batch processing systems; counting takes place

only at the review period. The Fixed-time Period models require a larger average inventory

because it must also protect against stock out during the review period; while the fixed-order

quantity mode has no review period.

These differences and the nature of operations tend to influence the choice of the inventory

system that is more appropriate.

11.3 Fixed-order Quantity Modeling

In this unit we will consider Fixed-order Quantity i.e. inventory models in which demand is

assumed to be fixed and completely predetermined. The heart of inventory analysis resides in

the identification of relevant costs.

11.3.1 Uncertainty in Demand and Lead Time

Inventory systems have to cope with uncertainty. You have to decide on when to order and how

much to order with a view minimization of costs, maximization of profit, or maximization of

service level i.e. the objectives stated by the organization.

The most common way to estimate demand is to collect data about past experience and forecast

future demand based on that data. However, in re-order point models the probability distribution

of demand during the lead-time is an important characteristic in inventory management. There is

also uncertainty in demand, in costs, in lead-time and in supplied quantity

It is often assumed that demand for an item is formed from a large number of smaller demands

from individual customers. As a result, the resulting demand is continuous and follows a Normal

LOVELY PROFESSIONAL UNIVERSITY 257