Page 53 - DMGT501_OPERATIONS_MANAGEMENT

P. 53

Unit 2: Product and Service Design

defining as a Universal Vehicle… the logic of this type of conversion of a sedan to the Universal Vehicle is Notes

the use of mass production technology in the manufacture of aggregates, so as to minimize the cost of built-

up products….

If the objectives for 1987-88, is laid down to capture 50 per cent of the car, jeep and light commercial vehicle

market and defence requirements, the domestic sales will be of the order of 70,500 units, including spare

parts requirements. With a focus on this type of volume, the project becomes economically viable."

The key to successful product development is to know what features or parts of the end product

need to be customized to meet the expectations of the target customers.

2.10 Design for Manufacturability (DFM)

1. DFM is the process of designing a product for efficient production while maintaining the

highest level of quality.

2. It is intended to avoid more complex and expensive product designs to simplify assembly

operations.

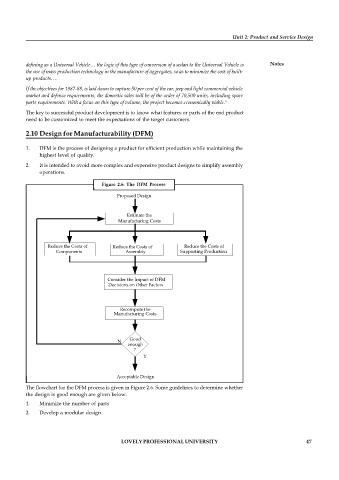

Figure 2.6: The DFM Process

Proposed Design

Estimate the

Manufacturing Costs

Reduce the Costs of Reduce the Costs of Reduce the Costs of

Components Assembly Supporting Production

Consider the Impact of DFM

Decisions on Other Factors

Recompute the

Manufacturing Costs

Good

N

enough

?

Y

Acceptable Design

The flowchart for the DFM process is given in Figure 2.6. Some guidelines to determine whether

the design is good enough are given below:

1. Minimize the number of parts

2. Develop a modular design

LOVELY PROFESSIONAL UNIVERSITY 47