Page 183 - DMGT524_TOTAL_QUALITY_MANAGEMENT

P. 183

Total Quality Management

Notes the probability of detection so that it would be possible to take remedial action whilst in

operation.

Conclusion

Using a technique such as Failure Modes and Effects Analysis allowed us to systematically

identify the risks in a mechanism design, quantify those risks with relative ratings and

recommend design changes to increase the probability of product success. This process

was used as a very effective tool for verifying if the proposed layout and design of the

mechanism adequately coped with the failure modes that would predictably occur during

machine operation.

Source: http://www.icubedtechnologies.com/csFMEA.php

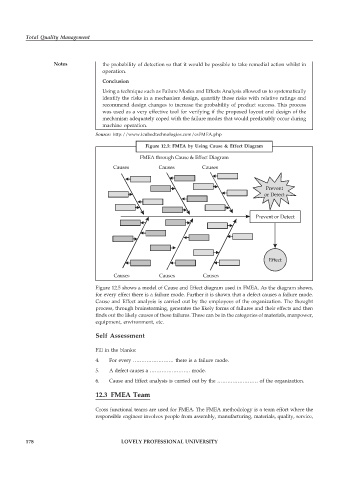

Figure 12.5: FMEA by Using Cause & Effect Diagram

FMEA through Cause & Effect Diagram

Causes Causes Causes

Prevent

or Detect

Prevent or Detect

Effect

Causes Causes Causes

Figure 12.5 shows a model of Cause and Effect diagram used in FMEA. As the diagram shows,

for every effect there is a failure mode. Further it is shown that a defect causes a failure mode.

Cause and Effect analysis is carried out by the employees of the organization. The thought

process, through brainstorming, generates the likely forms of failures and their effects and then

finds out the likely causes of these failures. These can be in the categories of materials, manpower,

equipment, environment, etc.

Self Assessment

Fill in the blanks:

4. For every …………………… there is a failure mode.

5. A defect causes a …………………… mode.

6. Cause and Effect analysis is carried out by the …………………… of the organization.

12.3 FMEA Team

Cross functional teams are used for FMEA. The FMEA methodology is a team effort where the

responsible engineer involves people from assembly, manufacturing, materials, quality, service,

178 LOVELY PROFESSIONAL UNIVERSITY