Page 207 - DMGT524_TOTAL_QUALITY_MANAGEMENT

P. 207

Total Quality Management

Notes By interpreting data and graph trends, forecasting of critical quality attributes, sigma

process capability, and stability of process were studied. The overall study contributes to

an assessment of process at the sigma level with respect to out-of-specification attributes

produced. Finally, the study will point to an area where the application of quality

improvement and quality risk assessment principles for achievement of six sigma-capable

processes is possible.

Statistical process control is the most advantageous tool for determination of the quality

of any production process. This tool is new for the pharmaceutical tablet production

process. In the case of pharmaceutical tablet production processes, the quality control

parameters act as quality assessment parameters. Application of risk assessment provides

selection of critical quality attributes among quality control parameters. Sequential

application of normality distributions, control charts, and capability analyses provides a

valid statistical process control study on process. Interpretation of such a study provides

information about stability, process variability, changing of trends, and quantification of

process ability against defective production. Comparative evaluation of critical quality

attributes by Pareto charts provides the least capable and most variable process that is

liable for improvement. Statistical process control thus proves to be an important tool for

six sigma-capable process development and continuous quality improvement.

Source: http://journal.pda.org/content/66/2/98.abstract

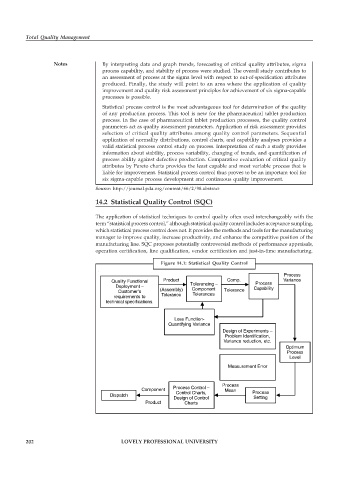

14.2 Statistical Quality Control (SQC)

The application of statistical techniques to control quality often used interchangeably with the

term “statistical process control,” although statistical quality control includes acceptance sampling,

which statistical process control does not. It provides the methods and tools for the manufacturing

manager to improve quality, increase productivity, and enhance the competitive position of the

manufacturing line. SQC proposes potentially controversial methods of performance appraisals,

operation certification, line qualification, vendor certification and just-in-time manufacturing.

Figure 14.1: Statistical Quality Control

Process

Quality Functional Product Comp. Process Variance

Deployment – Tolerancing – Capability

Customer’s (Assembly) Component Tolerance

Tolerances

requirements to Tolerance

technical specifications.

Loss Function-

Quantifying Variance

Design of Experiments –

Problem Identification,

Variance reduction, etc.

Optimum

Process

Level

Measurement Error

Process

Process Control –

Component Mean

Control Charts, Process

Dispatch

Design of Control Setting

Product Charts

202 LOVELY PROFESSIONAL UNIVERSITY