Page 211 - DMGT524_TOTAL_QUALITY_MANAGEMENT

P. 211

Total Quality Management

Notes

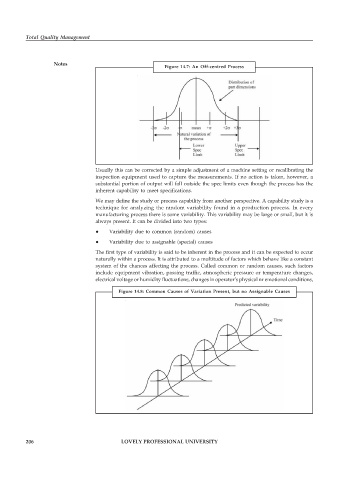

Figure 14.7: An Off-centred Process

Usually this can be corrected by a simple adjustment of a machine setting or recalibrating the

inspection equipment used to capture the measurements. If no action is taken, however, a

substantial portion of output will fall outside the spec limits even though the process has the

inherent capability to meet specifications.

We may define the study or process capability from another perspective. A capability study is a

technique for analyzing the random variability found in a production process. In every

manufacturing process there is some variability. This variability may be large or small, but it is

always present. It can be divided into two types:

Variability due to common (random) causes

Variability due to assignable (special) causes

The first type of variability is said to be inherent in the process and it can be expected to occur

naturally within a process. It is attributed to a multitude of factors which behave like a constant

system of the chances affecting the process. Called common or random causes, such factors

include equipment vibration, passing traffic, atmospheric pressure or temperature changes,

electrical voltage or humidity fluctuations, changes in operator’s physical nr emotional conditions,

Figure 14.8: Common Causes of Variation Present, but no Assignable Causes

206 LOVELY PROFESSIONAL UNIVERSITY