Page 64 - DCOM202_COST_ACCOUNTING_I

P. 64

Cost Accounting – I

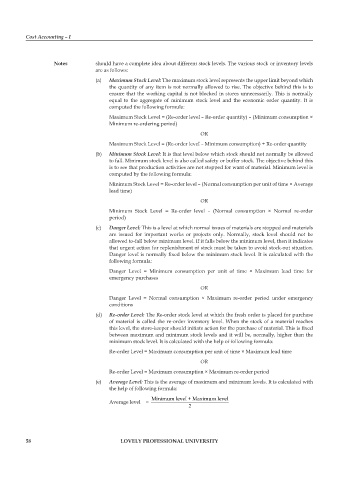

Notes should have a complete idea about different stock levels. The various stock or inventory levels

are as follows:

(a) Maximum Stock Level: The maximum stock level represents the upper limit beyond which

the quantity of any item is not normally allowed to rise. The objective behind this is to

ensure that the working capital is not blocked in stores unnecessarily. This is normally

equal to the aggregate of minimum stock level and the economic order quantity. It is

computed the following formula:

Maximum Stock Level = (Re-order level – Re-order quantity) – (Minimum consumption ×

Minimum re-ordering period)

OR

Maximum Stock Level = (Re-order level – Minimum consumption) + Re-order quantity

(b) Minimum Stock Level: It is that level below which stock should not normally be allowed

to fall. Minimum stock level is also called safety or buffer stock. The objective behind this

is to see that production activities are not stopped for want of material. Minimum level is

computed by the following formula:

Minimum Stock Level = Re-order level – (Normal consumption per unit of time × Average

lead time)

OR

Minimum Stock Level = Re-order level – (Normal consumption × Normal re-order

period)

(c) Danger Level: This is a level at which normal issues of materials are stopped and materials

are issued for important works or projects only. Normally, stock level should not be

allowed to-fall below minimum level. If it falls below the minimum level, then it indicates

that urgent action for replenishment of stock must be taken to avoid stock-out situation.

Danger level is normally fixed below the minimum stock level. It is calculated with the

following formula:

Danger Level = Minimum consumption per unit of time × Maximum lead time for

emergency purchases

OR

Danger Level = Normal consumption × Maximum re-order period under emergency

conditions

(d) Re-order Level: The Re-order stock level at which the fresh order is placed for purchase

of material is called the re-order inventory level. When the stock of a material reaches

this level, the store-keeper should initiate action for the purchase of material. This is fixed

between maximum and minimum stock levels and it will be, normally, higher than the

minimum stock level. It is calculated with the help of following formula:

Re-order Level = Maximum consumption per unit of time × Maximum lead time

OR

Re-order Level = Maximum consumption × Maximum re-order period

(e) Average Level: This is the average of maximum and minimum levels. It is calculated with

the help of following formula:

Minimum level + Maximum level

Average level =

2

58 LOVELY PROFESSIONAL UNIVERSITY