Page 72 - DMGT501_OPERATIONS_MANAGEMENT

P. 72

Operations Management

Notes 2. Input measures are generally used for low-volume, flexible processes.

Example: In a machine shop, capacity can be measured in machine hours or number of

machines.

Demand, which invariably is expressed as an output rate, must be converted to an input

measure. This conversion is required to compare demand requirements and capacity on

an equivalent basis. Capacity, then, may be measured in terms of the inputs or the outputs

of the conversion process.

However, converting demand into input measures may be quite difficult. In a general business

sense, capacity is most frequently viewed as the amount of output that a system is capable of

achieving over a specific period of time.

3.3 Determinants of Effective Capacity

Most of the capacity plans are based on the following:

1. Set time and resource allocation to meet demand;

2. Set strategies for meeting new requirements (new demand, competition, time changes for

projects, etc.); and

3. Determine the cost of non-conformance to the plan (waste, time slippage, costs, variance

in quality, etc.).

Determinants of effective capacity are:

1. Facilities

2. Product and service factors

3. Process factors

4. Human factors

5. Operational factors

6. Supply chain factors

7. External factors

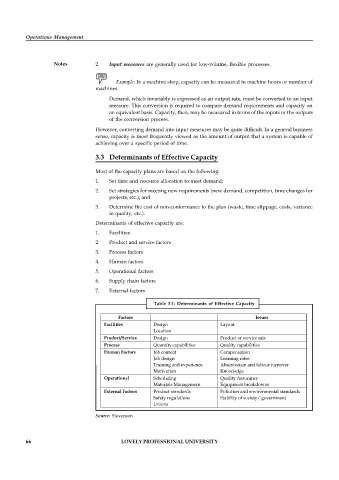

Table 3.1: Determinants of Effective Capacity

Factors Issues

Facilities Design Layout

Location

Product/Service Design Product or service mix

Process Quantity capabilities Quality capabilities

Human Factors Job content Compensation

Job design Learning rates

Training and experience Absenteeism and labour turnover

Motivation Knowledge

Operational Scheduling Quality Assurance

Materials Management Equipment breakdowns

External Factors Product standards Pollution and environmental standards

Safety regulations Stability of society/ government

Unions

Source: Stevenson

66 LOVELY PROFESSIONAL UNIVERSITY