Page 238 - DMGT524_TOTAL_QUALITY_MANAGEMENT

P. 238

Unit 14: Statistical Process Control

Process capability Cpk on 4th day from 12:00 to 13:00 shows that machine A has Cpk=1.276 Notes

a marginal process, machine D has Cpk =1.413 a capable process. All other machines show

that process is not capable with these specifications. Moreover, Cpk < 0 of machines E

implies that the process mean lies outside the specification limits.

Process capability Cpk on 5th day from 13:00 to 14:00 shows that machines C & F have Cpk

=1.696 & Cpk = 1.352, respectively show capable process. Machine E has Cpk =1.016, a

marginal process. The Cpk < 0 of Machines A implies that the process mean lies outside

the specification limits. The Cpk < -1 of Machine B shows that entire process lies outside

the specification limits and portrays the extreme situation of variability. It is also confirmed

by the lower value of Cr = -2.738. Therefore, Machines A and B give losses in production

and are not capable with the process.

Process capability Cpk on 6th day shows that machines B, D & F gives Cpk =1.089, Cpk

=0.967 & Cpk = 1.130, respectively, show a barely marginal process. All other machines

have process spread greater than specification limits. The Cpk < 0 of Machines A implies

that the process mean lies outside the specification limits.

Conclusions

It is a remote probability of a capable process. For machines A, B, C and F it is 1/6. Only for

machine B and D this probability is 1/3. The chance that machine E will achieve a process

capability is zero.

The categories marginal and capable process is combined. The probabilities for combined

processes are as: For machines A and F ½, B, C, D and E 1/3.

The probability that Cpk < 0 is 1/6 for machines C, D, E & F and 1/3 for machines A and B.

It shows the chance that process mean can go beyond the specification limits. The probability

that Cpk < - 1 for machines B and D is 1/6. It shows the chance that entire process lies

outside the specification limits. It should be taken care off.

Thus, in general, position of machines is good with reference to the process capability. But

to take care of isolated points, i.e. Cpk < -1 for machines B and D, HFL is suggested to

introduce high technology to reduce the variability and insure the process capability.

Questions

1. Based on the case discussed above bring out the importance of process capability

2. Do a brief analysis of the case in your own words

Source: http://www.gcu.edu.pk/fulltextjour/stat/stat-journal2005/sarwatzahra-article2.pdf

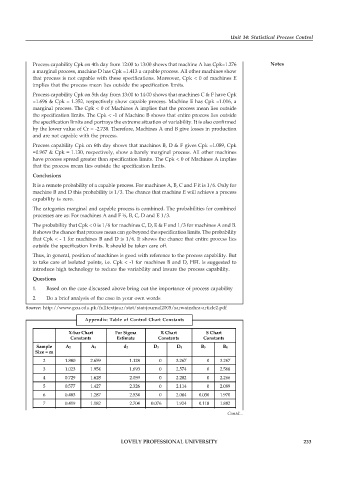

Appendix: Table of Control Chart Constants

X-bar Chart For Sigma R Chart S Chart

Constants Estimate Constants Constants

Sample A2 A3 d2 D3 D4 B3 B4

Size = m

2 1.880 2.659 1.128 0 3.267 0 3.267

3 1.023 1.954 1.693 0 2.574 0 2.568

4 0.729 1.628 2.059 0 2.282 0 2.266

5 0.577 1.427 2.326 0 2.114 0 2.089

6 0.483 1.287 2.534 0 2.004 0.030 1.970

7 0.419 1.182 2.704 0.076 1.924 0.118 1.882

Contd...

LOVELY PROFESSIONAL UNIVERSITY 233